Ceramic coatings

Ceramic coatings

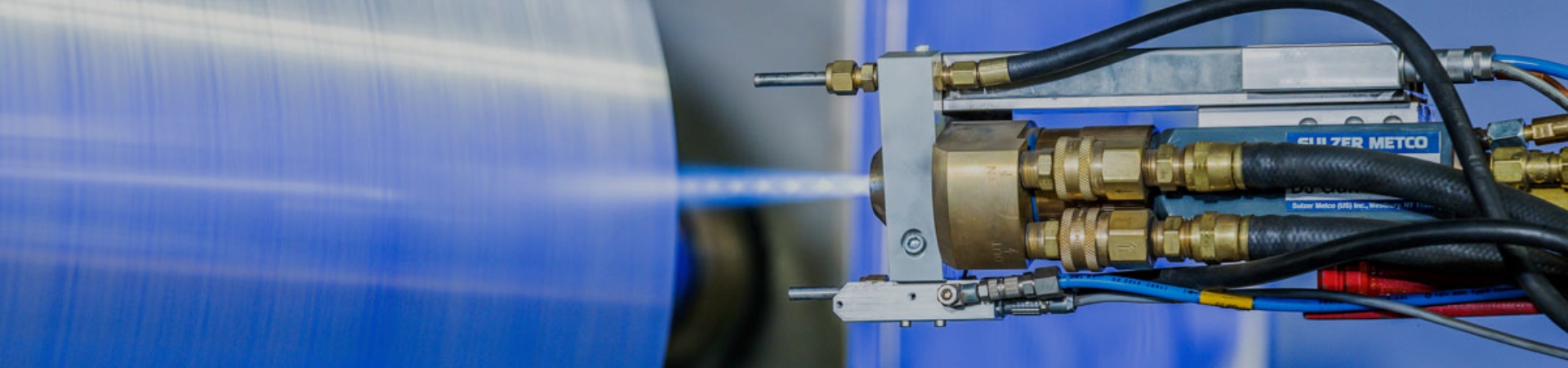

Ceramic coatings include alumina, titania, zirconia, chromium oxide, silicon carbide, silicon nitride, boron carbide, as well as oxides of many of these materials. It can provide wear protection to guide rollers for films, fibers, paper and cardboard. In recent years, it has also been active in biomaterials. Usually the plasma coating system to spray ceramic powder material with the temperature range from 18000℃ to 30000℃. As an industry coating leader, ASEN can spray most kinds of ceramic material to CFRP roller under maximum 120℃ by our strong R&D capability (Please refer to CFRP Roller plasma coating live video here) . Grinding to mirror surface coatings may have excellent sliding properties which can avoid scratch web.

Main properties of ceramic coatings ◆ High chemical corrosion resistance ◆ Excellent wear resistance ◆ Oxidation resistance ◆ High degree of hardness ◆ Anti-static ◆ Mirror surface finished ◆ Excellent electrical insulation ◆ Apply to CFRP, aluminum, steel roller |